Robot Introduction

Here we introduce some examples of robot utilization and introduction.

The benefits of introducing robots are immeasurable and can greatly contribute to increased productivity.

In terms of productivity, production efficiency does not fluctuate, so production can be carried out as planned, and furthermore, 24-hour operation is possible.

In terms of personnel, manpower savings is the most important benefit.Robots can reduce the number of workers by replacing humans in the production process.The introduction of industrial robots is key in today's age of declining birthrates and aging populations, which make it difficult to secure human resources.

In addition, by introducing systems such as cameras, lasers, and sensors, it is possible to perform variety identification, image inspection, and even automation of teaching, thus contributing to the production of a wide variety of products in small lots.

Examples of Robot Introduction

Click on an item for more information.

Rubber stopper insertion device for plastic connectors

Laser engraving equipment

Equipment for laser engraving of cup-shaped workpieces.

Cycle time: 45 sec.

The robot removes cups placed at an arbitrary angle.

The marking position is angle compensated by camera recognition.

Since marking is performed on each of the top and bottom surfaces of the workpiece, the robot performs a front-to-back reversal.

This is the basic pattern when marking is required for multiple locations.

High-speed index feeding system with a GENKOTSU robot

This system uses a GENKOTSU robot to supply the indexes that are being inspected at high speed.

Cycle time 5.0sec/piece

Conventionally, operators have been supplying and unloading with a two-handed operation.The SCARA robot could not keep up with the cycle time and could not automate the process.The adoption of the GENKOTSU robot allowed us to clear the cycle time and automate the process.Cost-effective introduction was achieved by retrofitting existing indexing equipment with automated supply and discharge conveyors and robots.

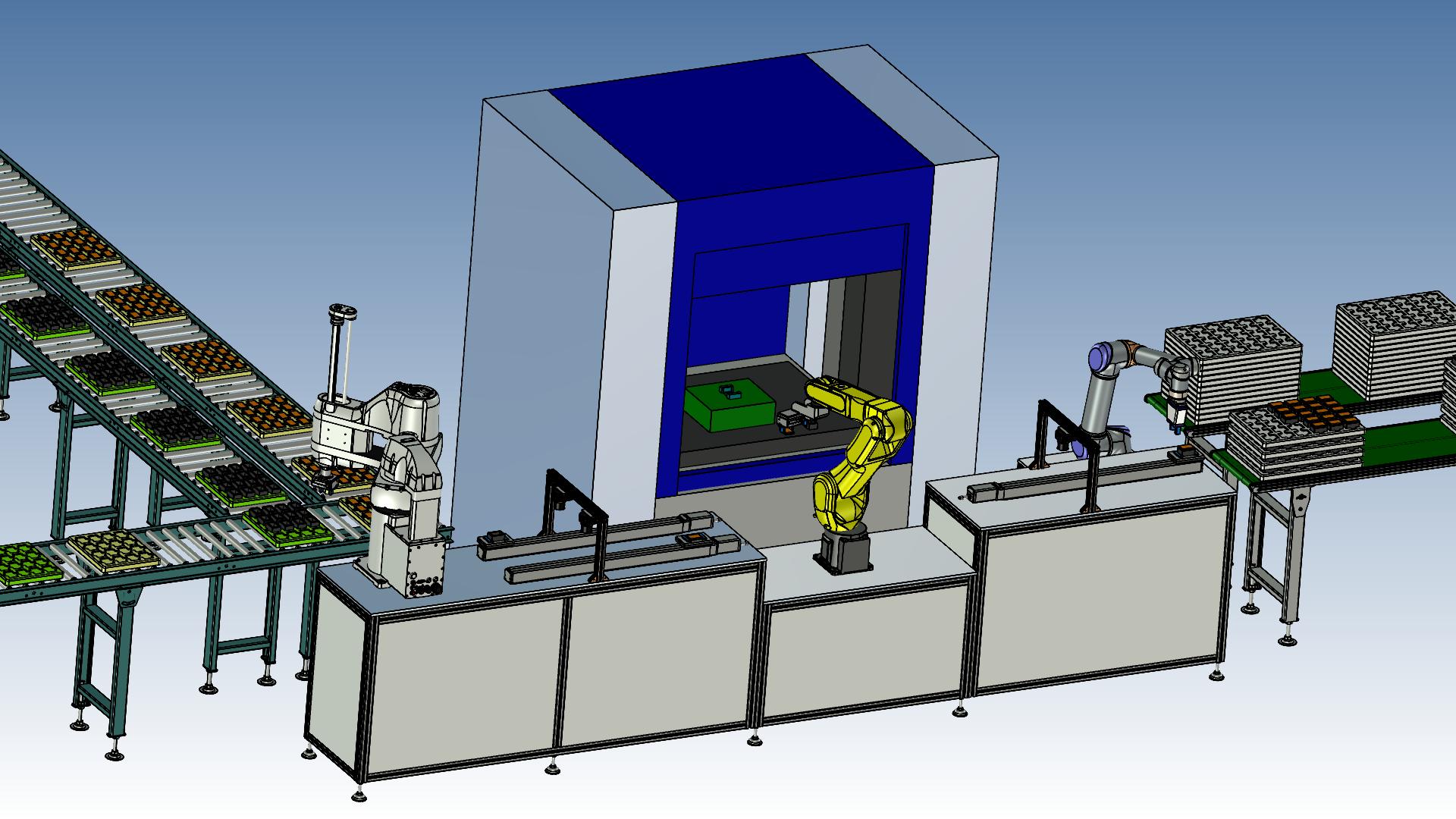

Processing machine loading device with cooperative robot

Cup Depalletizing device

Internal Diameter Measuring Equipment by Rank

This device measures the inside diameter of cup-shaped workpieces.

Cycle time: 40 sec.

Cups placed at an arbitrary angle are taken out by the robot and angle-corrected by the camera and fed into the measuring tool.Measured using Keyence GT sensor and paid out to the take-out table by measurement accuracy.

Robot Applications

.jpg) Conveyor Tracking

Conveyor Tracking.jpg) Deburring

Deburring.jpg) Processing machine loading

Processing machine loading%20(1).jpg) Universal Robots

Universal Robots%20(1).jpg) Disengagement action by force sensors

Disengagement action by force sensors%20(1).jpg) Weld Bead Inspection

Weld Bead Inspection

%20(1).jpg)